Dry cleaners management

EXCELLENCE IN THE SECTOR

What we offer

The software allows:

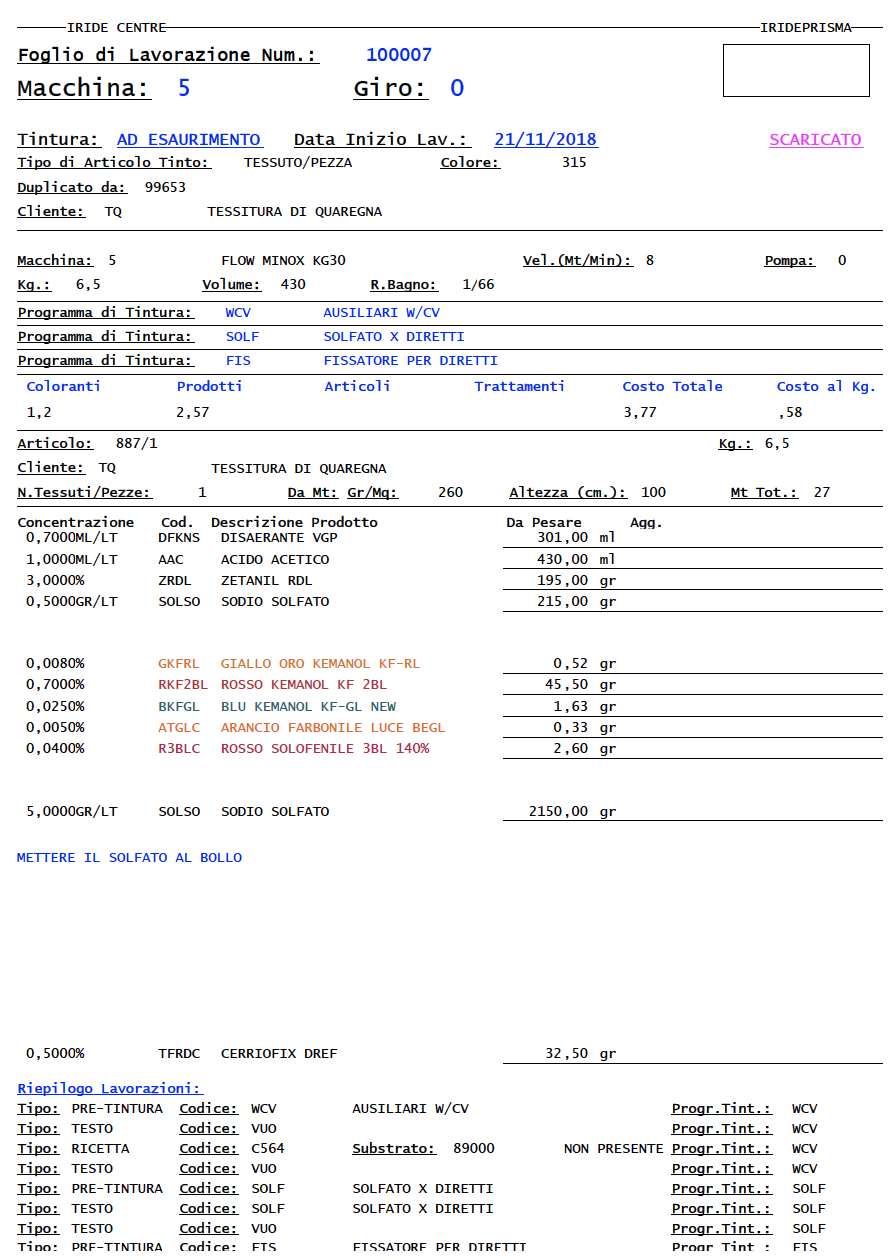

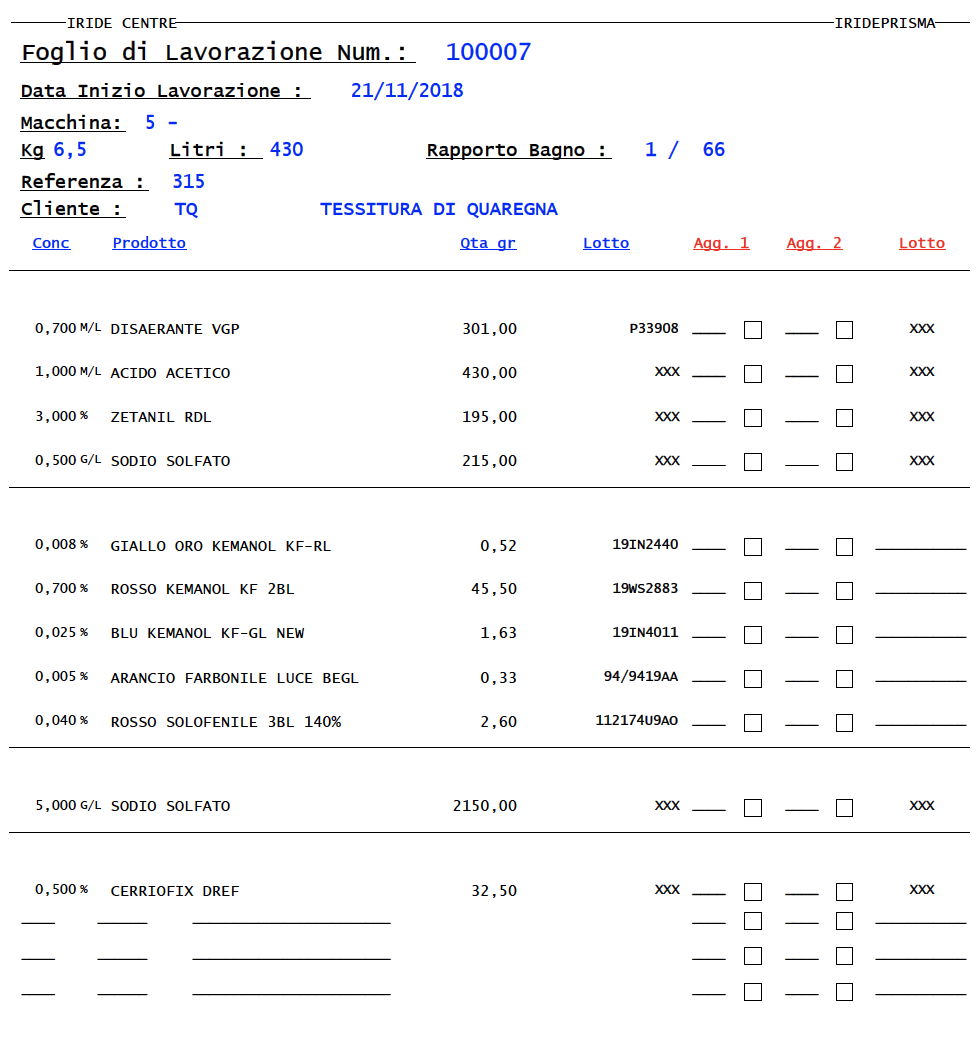

- to manage the worksheets

- to manage the dye warehouses

- to manage batches of dyes and auxiliaries for traceability

- to manage production shifts

- to obtain production statistics

What can you get

- Correct plant management

- Delivery of the goods on time

- The quality and responsiveness of the dyes

- The productivity of the dyeing machines

- Rationalization in the purchase and use of dyes and auxiliary products

- The analysis of production cycles

and much much more!

It allows you to store references, dyes, production recipes.

It allows you to store customers, suppliers, chemicals, product groups, articles, fiber composition, processes, dyeing machines, texts, causal references, cost centers, types of warehouse handling, additional treatments, etc.

It allows to manage the processing sheets for the production both for exhaustion dyes and for continuous dyes, with a very simple method of research, duplication and variation. It is also possible to create curves for auxiliary products based on the total concentration of the recipe or the weight of the material to be dyed or the liters of bath, to keep the various processing phases separate (pre-dyeing) , dyeing, finishing) and to manage the dyeing machines. It is also possible to calculate the recipe and industrial costs of the finished processing sheets.

It allows you to manage the handling of dyes, auxiliary products and raw materials, to print a brogliaccio and a warehouse inventory and to know at any time what the minimum sub-stock products are and their commitment in production.

It allows you to optimize production shifts.

It allows you to enter one or more batches of dyes and auxiliary products with the relative code and quantity, to indicate which batch is currently in use, to eliminate batches running out, choosing whether or not to move the residual quantity in the new active batch.

It allows you to manage the stock of the product: total or divided into lots, with the possibility, during the printing of the processing sheets, to highlight the lots associated with the relative products.

During the unloading of the processing sheets, it allows to manage automatically or manually the association of active lots with the products, with relative control if the residual quantity in the active lot is less than the actual quantity to be unloaded.

It allows you to search and print all the processing sheets produced with a specific batch in a period of time.

It allows you to query the system on the quantities of raw material dyed according to the customer, the reference, the article, the substrate and the type of shade (light, medium, dark, bright), in a certain period of time and to calculate the related costs, to know the reasons for the pick-ups and the distribution of the loads of the dyeing machines.

It allows you to view the costs and consumption of dyes and auxiliary products and raw materials in a certain period of time divided by production department and highlight the loading and unloading movements.

It allows you to define multiple interchangeable work environments.

It allows the end user to parameterize the program to their working needs.

Customizations and configurable options

- Technical Management of the Melange Department: Allows you to perform the entire production cycle of the mélange starting from components in batches of tops or staple, used both colored and undyed. With the possibility to view and print at any time every single product, dye or auxiliary, used in dyeing, the average percentage used up to that time of work and the percentage used to dye each single bath. Furthermore, at the end of the processing, it is possible to store the individual medium recipes of components and mélange.

- Connection to industrial dosing systems: Allows you to send the quantities of dyes and auxiliary products automatically or to be manually dosed to the production dosers.