Colorimetry and management for printing works

EXCELLENCE IN THE SECTOR

What we offer

The software allows:

- to recreate new colors or to research and correct colors already produced

- to correct laboratory and production recipes

- to recover the printing pastes

- to manage drawings, variants and paintings

- to control the color of the samples according to the internationally standardized control formulas and with the ellipsoidal method

- to check and archive the Solidity Tests

- to check incoming raw materials

What can you get

- Correct plant management

- Delivery of the goods on time

- The quality and correspondence of the prints

- Productivity of printing machines

- Rationalization in the purchase and use of pigments / inks and auxiliary products

and much much more!

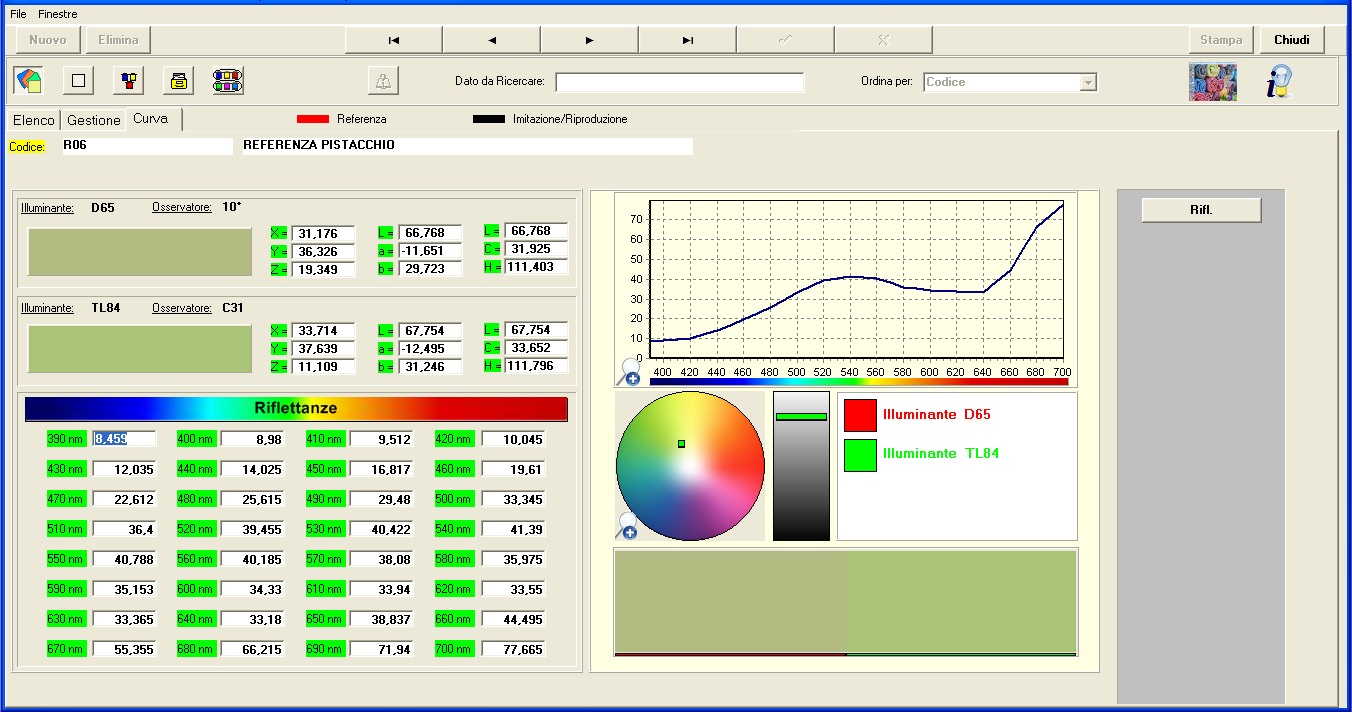

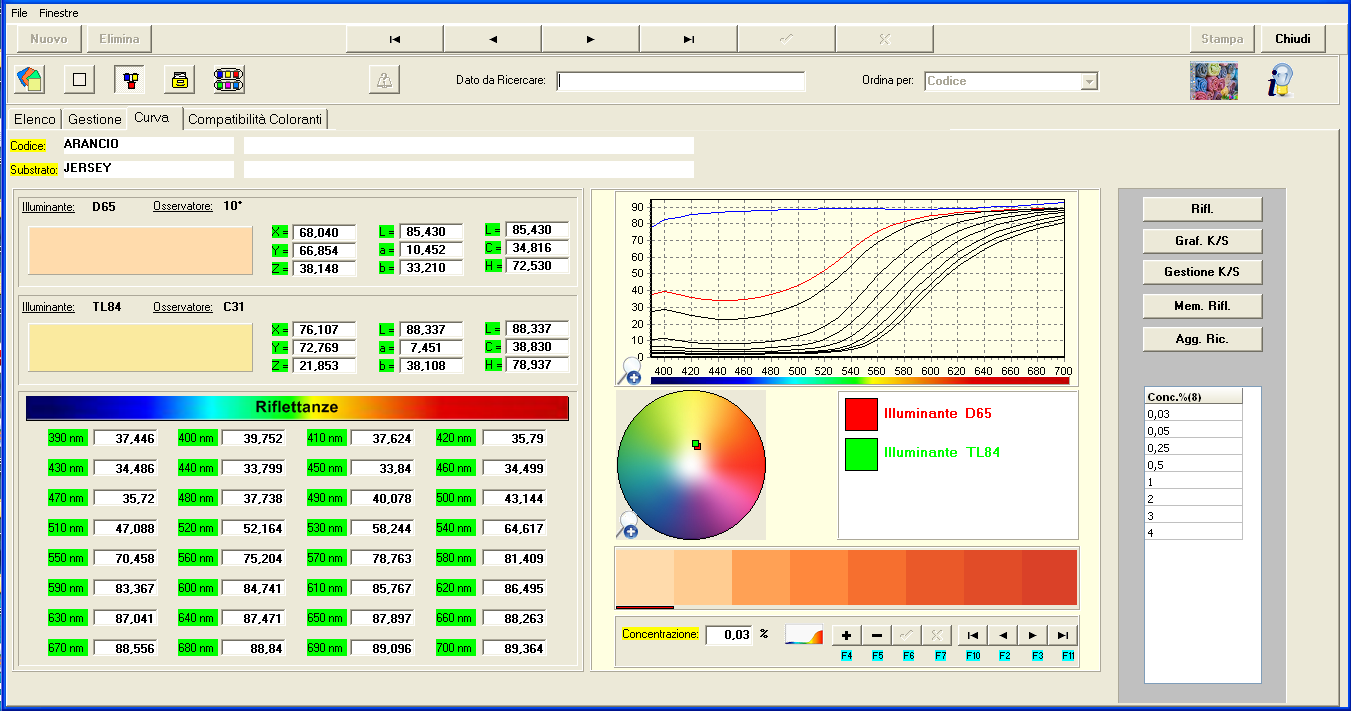

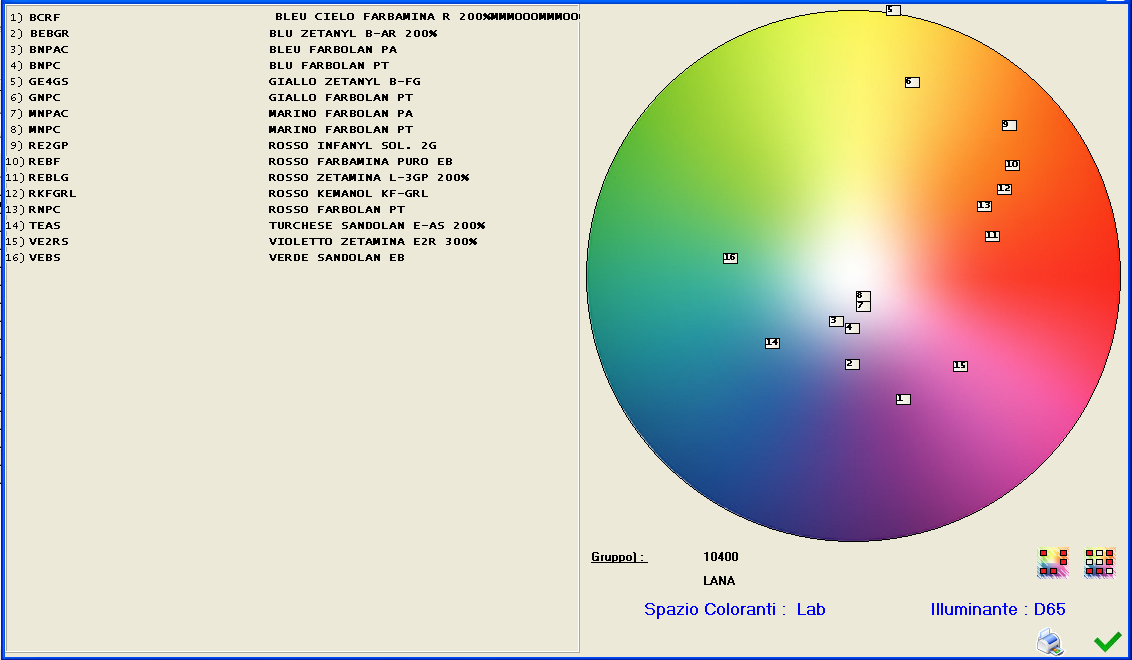

It allows you to store references by code or by drawing / variant / framework, imitations, substrates, pigments / inks with the relative strength and concentration values of the mother, laboratory and production recipes and groups of dyes depending on the use for which they are intended , color charts and drawings with their variants, paintings, recipes and provisions to be sent for processing.

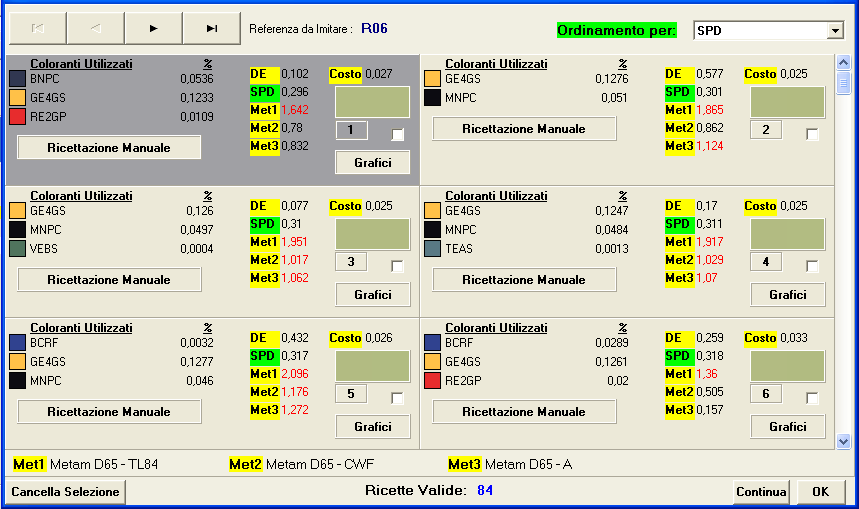

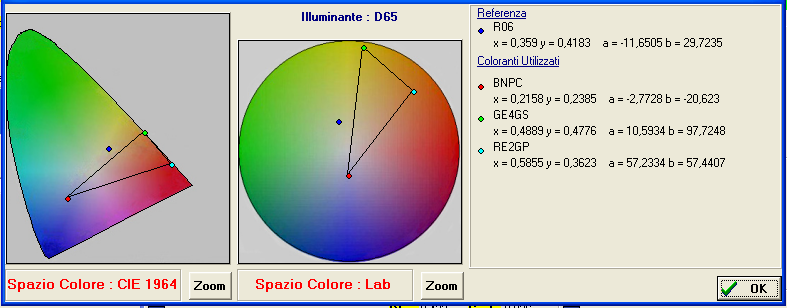

It allows you to recipe according to the user's needs in different ways: multiple, single, manual, optimized to obtain the best recipe with the least number of pigments / inks, with search in the historical archive of recipes, sampling drawings with the possibility of sampling the variants of a design also stored on several substrates, for the management of Composes, based on DSP (Simpson Spectral Difference), dE, metameria and price.

It allows to recover the printing pastes gathered by shades or separate seals.

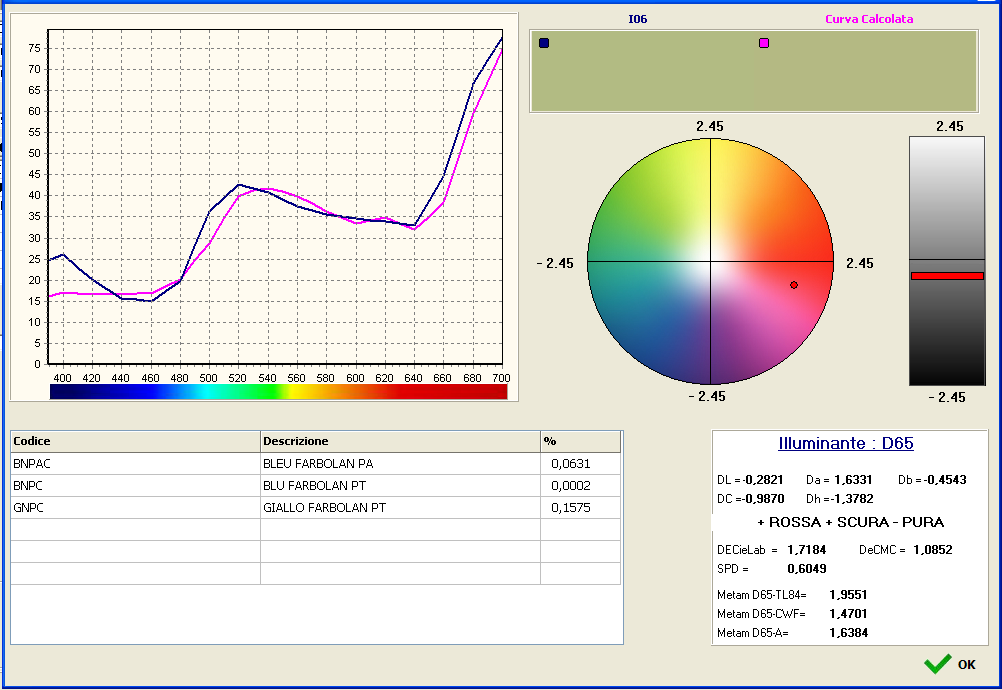

It allows you to correct laboratory and production recipes, always returning the calculations to positive additions of parts and cutting and calculation of recipes for pre-dyed substrates.

It allows you to control colors in accordance with the most important international formulas (CIELab, CMC I: c, etc.) and with the Ellipsoidal method.

It allows to analyze instrumentally the color fastness according to the ISO standard referred to the Gray Scale.

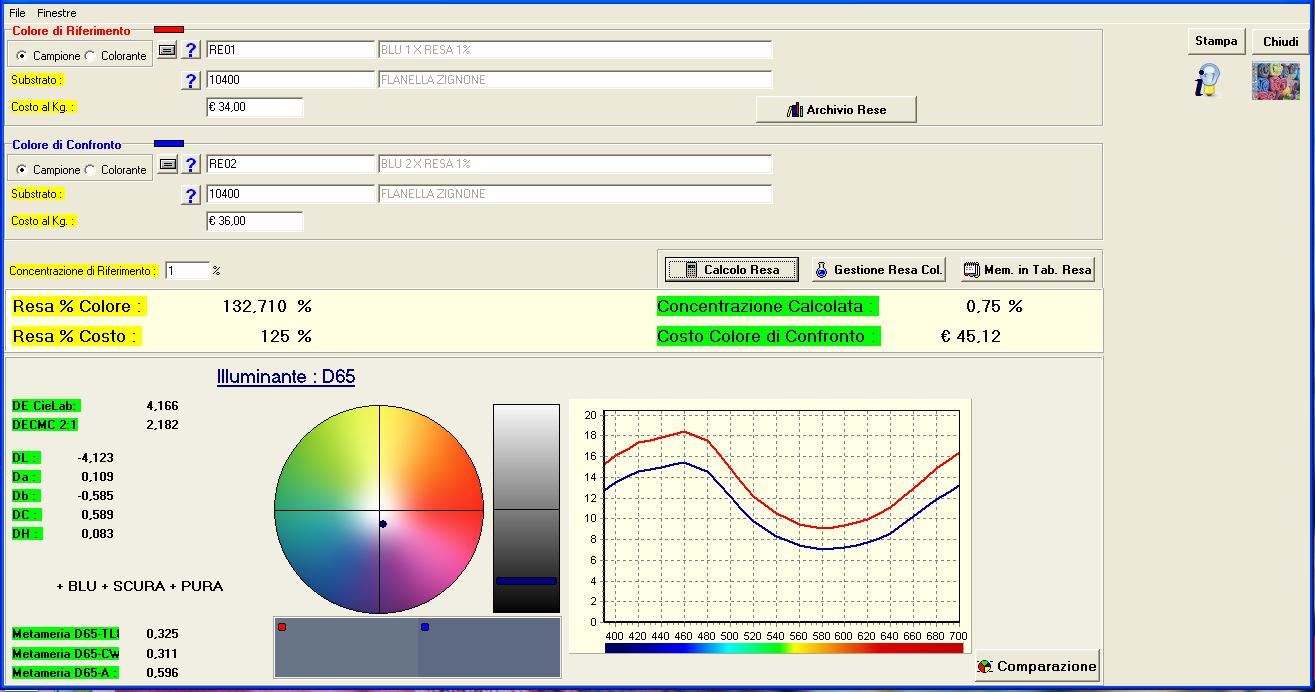

It allows to calculate the color / price rendering between the same pigments / inks for the Color Index or different lots of the same pigment / ink.

It allows you to define multiple interchangeable work environments.

It allows the end user to parameterize the program to their working needs.

Customizations and configurable options

- Production management: Allows you to associate the auxiliary products to each drawing to print the stored arrangements and the processing sheets for the color kitchen.

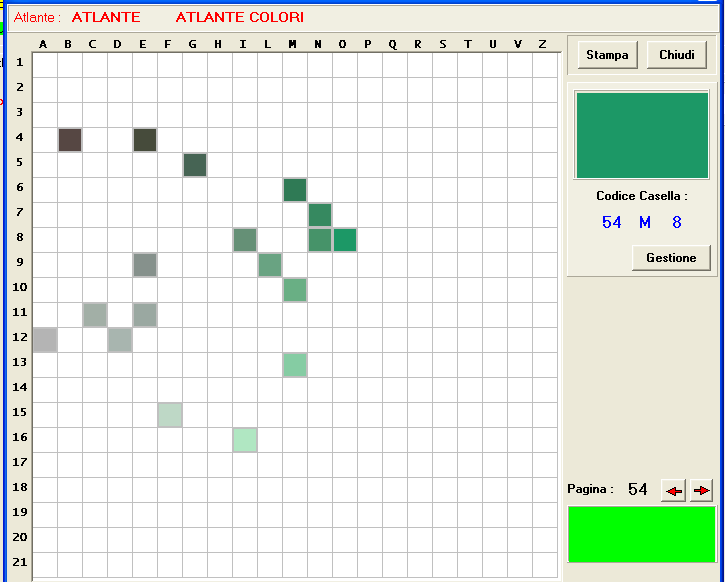

- Atlas Colors: Allows you to dynamically manage user-defined color atlases, with variable pages and tolerances for an optimization of the colors produced and with the possibility of transferring to prototyping systems.

- Connection to laboratory and industrial dosing systems: Allows to send the quantities of pigments / inks calculated in receiving and correcting directly to laboratory or production dosers.

- Import and Export Data in QTX format: Allows you to import, in the sample archive, the readings of a client's standards in QTX format and export the results obtained always in the same format.